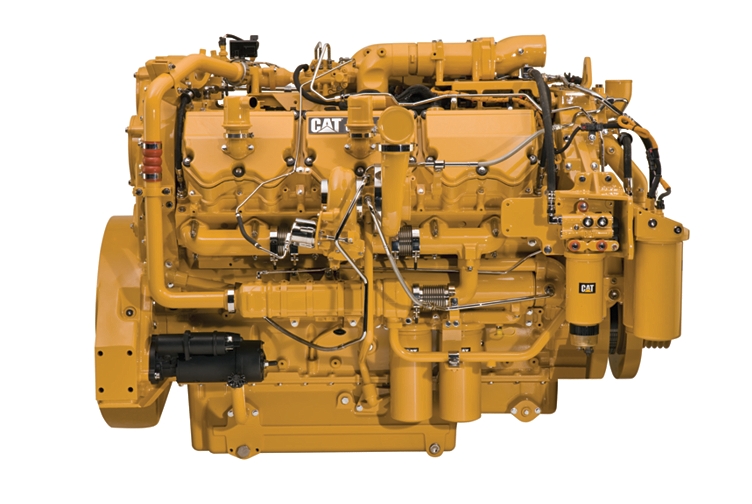

Cat C32 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C32 ACERT engines to deliver excellent performance with low operating costs while meeting the tightest environmental requirements.This is an ideal engine for applications that require Tier 4 Final emissions certifications in well service application such as well stimulation pumping, pump skids, nitrogen units, acidizing units, blenders, and hydraulic power units.Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty.C32 ACERT engines, rated 839 bkW (1125 bhp) @ 1800 rpm, designed to meet U.S. EPA Tier 4 Final emission standards. This information about Emissions describes the particular rating’s emissions technology. For more information about emissions certification, please contact your local Cat dealer.