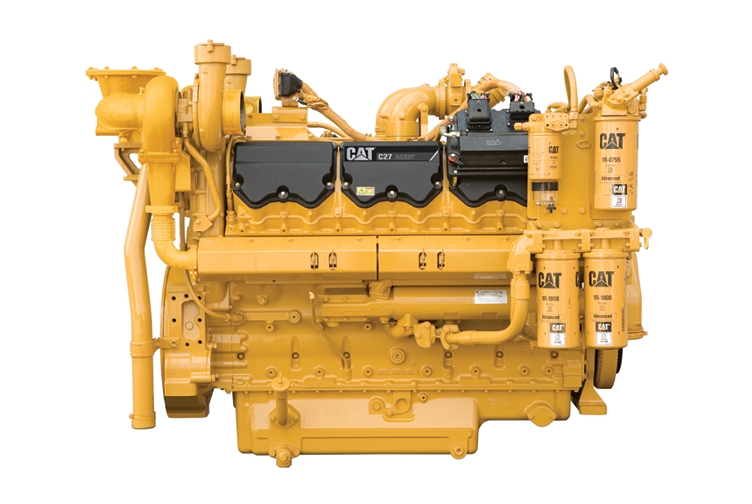

Cat C27 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C27 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C27 ACERT engines include well stimulation pumping, pump skids, nitrogen units, acidizing units, blenders, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. C27 ACERT engines, with ratings: 597-858 bkW (800-1150 bhp) @ 1800-2100 rpm, meet U.S. EPA Tier 2 equivalent emission standards. They are available using U.S. EPA Flexibility, and for other regulated and non-regulated areas.

| Maximum Rating | 1050BHP |

| Displacement | 1658in³ |

| Minimum Rating | 800BHP |

| Governor and Protection | ADEM A3 |

| Aspiration | Turbocharged-Aftercooled |

| Flywheel and Flywheel Housing | SAE No. 0 or SAE No. 1 |

| Flywheel Teeth | 136 (SAE No. 0), 113 (SAE No. 1) |

| Rotation from Flywheel End | Counterclockwise |

| Stroke | 6in |

| Bore | 5.4in |

| Emissions | 2006 EPA and CARB Tier 2, and EC Stage II Non-Road emissions certified |

| Length | 75.5in |

| Width | 57.6in |

| Height | 52in |

| Weight | 6382lb |

| Cooling System | 14.5gal (US) |

| Air Inlet System |

|

| Control System |

|

| Cooling System |

|

| Exhaust System |

|

| Flywheels And Flywheel Housings |

|

| Fuel System |

|

| Lube System |

|

| Mounting System |

|

| Power Take-offs |

|

| General |

|

| Air Inlet System |

|

| Charging System |

|

| Circuit Breakers |

|

| Cooling System |

|

| Exhaust System |

|

| Fuel Systems |

|

| Instrumentation |

|

| Lube System |

|

| Mounting System |

|

| Power Take-offs |

|

| Starting System |

|

| Packaging |

|