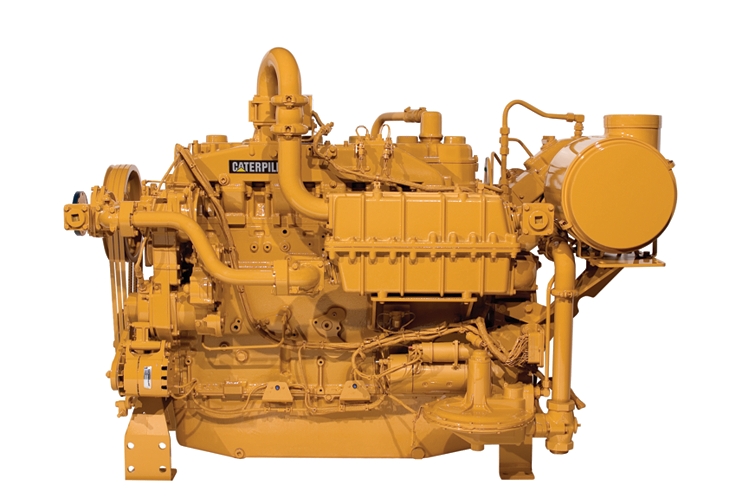

Tough and durable, built on the industry-standard G3300 platform and equipped with technology that brings performance, uptime, and low operating cost to your operation. G3304B engines meet the most demanding continuous duty gas compression applications with virtually no unscheduled downtime. Ideal applications for G3304B engines include gas lift, gas gathering, and wellhead gas compression. Cat G3304B gas engine. Ratings: 71 bkW (95 bhp) @ 1800 rpm are NSPS site compliant capable with Caterpillar or customer-provided air-fuel ratio control and aftertreatment.

| Maximum Rating | 95BHP |

| Rated Speed | 1800rpm |

| Emissions | Rich Burn: EPA NSPS Site Compliant Capable with Caterpillar or Customer Supplied AFRC & Aftertreatment |

| Minimum Rating | 95BHP |

| Compression Ratio | 10.5:1 |

| Aspiration | Naturally Aspirated |

| Rotation from Flywheel End | Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 1 |

| Flywheel Teeth | 156 |

| Weight - Dry | 2253.8lb |

| Length | 46in |

| Displacement | 425in³ |

| Oil Change Interval | 750 |

| Width | 29in |

| Ignition, Protection | ADEM™ A4 |

| Air/Fuel Ratio Control | ADEM™ A4 |

| Stroke | 6in |

| Bore | 4.75in |

| Cooling System | 4.23gal (US) |

| Lube Oil System - Refill | 8.19gal (US) |

| Air Inlet System |

|

| Control System |

|

| Cooling System |

|

| Exhaust System |

|

| Flywheels & Flywheel Housings |

|

| Fuel System |

|

| Ignition System |

|

| Lube System |

|

| Protection System |

|

| Charging Alternator |

|

| Cooling System |

|

| Exhaust System |

|

| Ignition System |

|

| Instrumentation |

|

| Starting System |

|