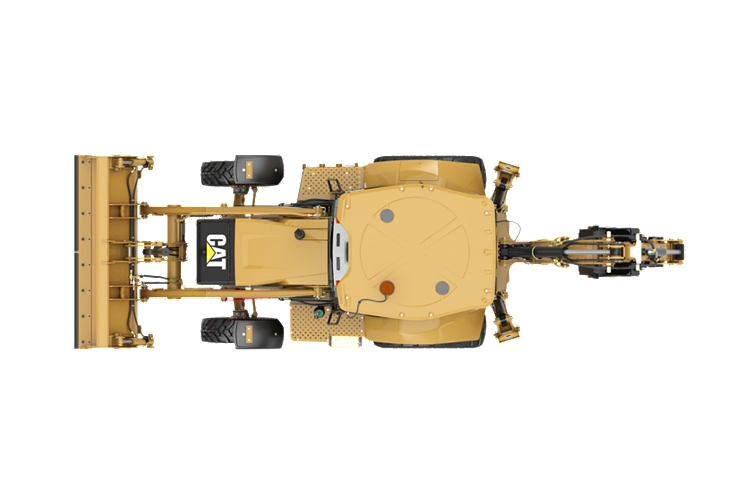

Experience the new Cat 415F2 Backhoe Loader with features including spacious operator station, optional pilot controls, superior durability and outstanding performance. Safely operate on the job site with quieter hydraulics, increased visibility, and the ability to have four wheel braking engaged without wearing on tires or drive train.

| Net Power - SAE J1349 | 68HP |

| Bore | 3.9in |

| Stroke | 4.33in |

| Displacement | 207in³ |

| Rated Net Power - 2,200 rpm - ISO 9249 | 68HP |

| Net Peak Power - 1,800 rpm - EEC 80/1269 | 73HP |

| Gross Power - ISO 14396 | 74HP |

| Net Power - 2,200 rpm - SAE J1349 | 68HP |

| Engine Model | Cat® C3.4B |

| Net Peak Power - 1,800 rpm - SAE J1349 | 72HP |

| Gross Power - SAE J1995 | 74HP |

| Net Peak Power - 1,800 rpm - ISO 9249 | 73HP |

| Rated Net Power - SAE J1349 | 68HP |

| Net Peak Torque - 1,400 rpm | 307ft-lb |

| Note | Engine meets U.S. EPA Tier 4 Final emission standards. |

| Net Torque Rise - 1,400 rpm - SAE J1349 | 88% |

| Rated Net Power - 2,200 rpm - EEC 80/1269 | 69HP |

| Rated Net Power - ISO 9249 | 68HP |

| Dig Depth - Standard | 14.3ft |

| Dig Depth - E-Stick Extended | 17.9ft |

| Operating Weight - Maximum | 24251lb |

| Cab - ROPS/FOPS | 359lb |

| Four Wheel Drive | 392lb |

| Counterweights - Option 1 | 255lb |

| Air Conditioning | 101lb |

| Counterweights - Option 2 | 530lb |

| Counterweights - Option 3 | 1015lb |

| Operating Weight - Maximum - ROPS Capacity | 24251lb |

| MP Bucket (0.96 m3/1.25 yd3) - No Forks or Teeth | 1642lb |

| Extendible Stick | 659lb |

| Pump Type | Variable Flow, Axial Piston |

| Type | Closed Center |

| Pump Capacity at 2,200 rpm | 35gal/min |

| System Pressure - Loader | 3336psi |

| System Pressure - Backhoe | 3336psi |

| Power Shuttle Transmission - Forward 1st | 3.4mile/h |

| Power Shuttle Transmission - Reverse 4th | 23mile/h |

| Power Shuttle Transmission - Reverse 3rd | 12mile/h |

| Power Shuttle Transmission - Reverse 1st | 3.4mile/h |

| Power Shuttle Transmission - Forward 4th | 23mile/h |

| Power Shuttle Transmission - Forward 3rd | 12mile/h |

| Power Shuttle Transmission - Forward 2nd | 5.5mile/h |

| Power Shuttle Transmission - Reverse 2nd | 5.5mile/h |

| Engine Oil - With Filter | 2.3gal (US) |

| Rear Axle | 4.4gal (US) |

| Rear Axle - Planetaries | 0.4gal (US) |

| Fuel Tank | 42gal (US) |

| Hydraulic System | 23.8gal (US) |

| Hydraulic Tank | 10.6gal (US) |

| Note | Requires ultra-low sulfur fuel less than or equal to 15 ppm fuel sulfur. |

| Transmission - Power Shuttle - 4WD | 4gal (US) |

| Front Axle (4WD) | 2.9gal (US) |

| Transmission - Power Shuttle - 2WD | 4gal (US) |

| Front Axle (4WD) - Planetaries | 0.2gal (US) |

| Cooling System with Air Conditioning | 5.8gal (US) |

| Rod Diameter | 1.4in |

| Stroke | 4.7in |

| Type | Front Wheel |

| Power Steering | Hydrostatic |

| Turning Circle - (inner wheel not braked) - Outside Front Wheels | 26.8ft |

| Axle Oscillation | 11° |

| Bore | 2.6in |

| Turning Circle - (inner wheel not braked) - Outside Widest Loader Bucket | 36ft |

| Front Axle (2WD) - Static | 50582lb |

| Front Axle (4WD) - Dynamic | 20233lb |

| Front Axle (2WD) - Dynamic | 20233lb |

| Front Axle (4WD) - Static | 50582lb |

| Rear Axle - Static | 50582lb |

| Rear Axle - Dynamic | 20233lb |

| Feature (3) | Foot operated brake pedals can be interlocked for roading. |

| Feature (5) | Parking brake is mechanically applied through an adjustable hand lever located on the right console. |

| Feature (2) | Self-adjusting, completely enclosed and sealed. |

| Feature (1) | Brakes meet the following standards: SAE J1473 and ISO 3450 requirements. |

| Feature (4) | Parking/secondary brakes are independent of the service brake system. |

| Feature (3) | Forged chrome/molybdenum-steel crankshaft with salt bath nitrocarburized pins and journals. |

| Feature (15) | Higher low end torque for better engine/machine performance. |

| Feature (5) | For durability, inlet valves are nitrided, martensitic chrome silicon steel. |

| Feature (7) | Cylinder block is high strength, cast iron alloy of deep skirt, monobloc design for increased strength and long life. |

| Feature (16) | Engine is equipped with electric fuel priming pump. |

| Feature (9) | Cylinder head's intake and exhaust ports are precision cast to promote optimum gas flow. |

| Feature (12) | Direct electric, 12-volt starting and charging system with 880 CCA Group 31 maintenance free battery. |

| Feature (1) | Regeneration is passive and does not require any input from the operator or disrupt work. |

| Feature (4) | Front and rear crankshaft oil seals are “lip” type Viton and PTFE designs featuring an integral dust lip. |

| Feature (6) | For durability, exhaust valves are nitrided, austenitic chrome manganese-nickel steel. |

| Feature (13) | Standard glow plug starting aid system for efficient cold weather starting. |

| Feature (2) | Three-ring pistons made of lightweight, silicon/aluminum alloy for strength and maximum thermal conductivity. |

| Feature (10) | Direct injection fuel system provides accurate fuel delivery and efficiency. |

| Feature (14) | High contact ratio/gear train, peripheral fixed isolation top cover and open deck block design reduce bare engine noise. |

| Feature (11) | Dry-type axial seal air cleaner with integral precleaner, automatic dust ejection system, and filter condition indicator. |

| Feature (8) | Cylinder head is high strength, cast iron alloy construction with extra duty wall and deck thickness. |

| Cab - ROPS | SAE J1040 MAY94; ISO 3741 1994 |

| Cab - FOPS | SAE J/ISO 3449 APR98 LEVEL II and ISO 3449: 1992 LEVEL II |

| Cab - Sound | ANSI/SAE J1166 OCT98 is 79 dB(A) |

| Brakes | SAE J/ISO 3450; ISO 3450 1996 |

| Exterior Sound | SAE J188 JUN86 is 76 dB(A) |

| Choice 5 | Front: 340-80R18 143B R-4; Rear: 500/70R24 157B, R-4 |

| Choice 1 | Front: 11L-16 (12 ply) F-3; Rear: 19.5L-24 (12 ply) R4 ATU |

| Choice 2 | Front: 12.5/80-18-1810 PR I-3; Rear: 19.5L-24 12 PR R4 |

| Choice 7 | Front: 340/80R18 XMCL 142A8; Rear: 500.70R24 XMCL 157A8 |

| Choice 3 | Front: 12-16.5 (10 ply); Rear: 19.5L-24 (12 ply) ATU |

| Choice 4 | Front: 12-16.5 (12 ply); Rear: 19.5L-24 (12 ply) ATU, 20 PITCH |

| Choice 6 | Front: 340-80R18 143B R-4; Rear: 19.5L-24, 12, ATU |